ECXT-6025 3000W fiber laser goynta mashiinka

Qaybta farsamada

Marka hore, sifooyinka alaabta

Isticmaalka laba geesoodka servo motor iyo habka wareegga hagaha, saxnaanta goynta sare, isticmaalka software xirfadeed bandhigay, waxay noqon kartaa bilaash si ay u naqshadeeyaan noocyo kala duwan oo garaafyada si ay u fuliyaan ama qoraal processing degdeg ah, processing dabacsan, hawl fudud, habboon.Lagu dabaqay goynta xawaaraha sare leh, oo leh xawaare sare iyo xasilooni.

1) Baaxadda codsiga

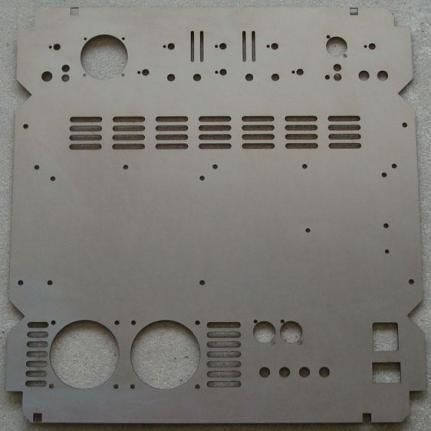

Ku habboon birta birta ah, birta kaarboonka, birta daawaha, birta silikoon, saxan bir galvanized ah, daawaha titanium nikkel, alloy inconel, alloy titanium iyo walxo kale oo bir ah.

Si ballaaran loo isticmaalo hawada, baabuurta iyo markabka, wax soo saarka mishiinada, wax soo saarka wiishka, wax soo saarka xayaysiis, soo saarista qalabka guriga, qalabka caafimaadka, hardware, qurxinta, adeegyada processing dibadda biraha iyo warshadaha kale ee wax soo saarka.

2) Faa'iidooyinka mashiinka goynta laser fiber

1. Tayada bim ee aad u fiican: meesha diiradda la saarayo waa yar tahay, xariiqda goynta ayaa ka sii fiican, waxtarka shaqada ayaa ka sarreeya, tayada farsamaynta ayaa ka sii fiican;

2, xawaaraha goynta aad u sarreeya: waa awood isku mid ah CO2 mashiinka goynta laser 2 jeer;

3, xasilloonida sare: isticmaalka laser fiber-ka ugu sarreeya adduunka, waxqabadka xasilloon, nolosha adeegga qaybaha muhiimka ah ilaa saacadaha 100,000;

4. Waxtarka is-beddelka elektaroonigga ah ee aad u sarreeya: mashiinka goynta laser fiber-ka ayaa 2 jeer ka sarreeya CO2 laser jarida waxtarka beddelka elektiroonigga ah, badbaadinta tamarta iyo ilaalinta deegaanka;

5, kharash aad u jaban oo isticmaalka: isticmaalka awoodda mishiinka oo dhan waa 20-kaliya ee CO2 mashiinada goynta laser la mid ah.

30;

6. Kharashka dayactirka aadka u hooseeya: ma laha gaas shaqeynaya laser;gudbinta fiber indhaha, looma baahna muraayadaha milicsiga;Kaydinta kharashka dayactirka ee muhiimka ah ayaa la gaari karaa;

7, hawlgalka alaabta iyo dayactirka waa ku haboon: gudbinta fiber indhaha, looma baahna in la hagaajiyo jidka indhaha;

8.Super saamaynta hagaha iftiinka dabacsan: cabbir yar, qaab-dhismeedka is haysta, shuruudaha farsamaynta fudud ee fudud.

(3) Goynta muunad samaynta samaynta

Marka labaad, cabbirada qalabka

| Qaabka | LFS6025-3000W |

| Goobta shaqada | 6050*2550 |

| Awoodda ugu badan ee laser | 3000W |

| Laqabsiga sare | Dabagalka diyaaradda |

| Balaadhka khadka ugu yar | 0.15mm |

| Inta jeer ee garaaca garaaca | 1-5000Hz |

| Ku celcelinta | ±0.02mm |

| Ujeedo meelaynta | Iftiin cas |

| Korontada | 380V/50Hz/60Hz/100A |

| Cabbirka mashiinka | 7880x3450x2000mm |

Saddexaad, qaabeynta ugu weyn

Magaca Nambarka Caadiga ah Qaabka/Taxanaha Magaca Tirada Soo Saaraha.

| Maya | Magaca alaabta | Model/taxane | Tirada | Soo saaraha |

| 一 | dhaliye laser | |||

| 1 | isha Laser | 3000w | 1 set | Cilmi-baarista wadajirka ah iyo horumarinta |

| 二 | Jidka indhaha ee dibadda iyo goynta madaxa | |||

| 1 | Madaxa goynta laser | auto diiradda | 1 set | Jiaqang |

| 三 | Qalabka mashiinka martigeliyaha | |||

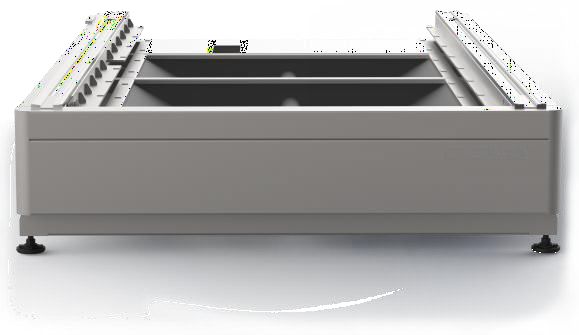

| 1 | Sariirta mashiinka | 6025 hal madal | 1 set | Makaanik heer sare ah |

| 2 | Tilmaamayaal toosan | HGL HA2R | 2 qaybood | Qiimaha ugu sarreeya ee Taiwan KING TEK |

| 3 | Servo motor iyo darawalka | 4 qaybood | Japan Fuji | |

| 4 | Dhidibiyaha XY ee meeraha meeraha | MAF-090 | 3 qaybood | Faransiiska Mordry |

| 5 | Gear/rack Helical | YYC 2M | 2 qaybood | YYC |

| 6 | Xakamaynta golaha | 1 set | Makaanik heer sare ah | |

| 7 | Qalabka qalabka mashiinka | 1 set | Makaanik heer sare ah | |

| Afar | CNC iyo nidaamka software | |||

| 1 | nidaamka CNC | Bai chu | 1 set | Shiinaha Bai chu |

| 2 | Kombiyuutarka warshadaha | 1 set | La habeeyay | |

| 3 | Qaybaha korantada | 1 set | Schneider | |

| Shan | Qalabka caadiga ah | |||

| 1 | Qaboojiyaha saxda ah | HL-3000 | 1 se' | Wuhan Hanli |

| 2 | Nidaamka buuxinta saliidda tooska ah | 1 set | koronto | |

| 3 | Qaboojiyaha heerkulka joogtada ah ee warshadaha | 1 set | ||

| 4 | Nidaamka daalka | 1 set | boos celinta dhuumaha | |

| 5 | Xasilinta | 1set | habaysan | |

| 6 | Qaadashada gawaarida | 1 set | habaysan | |

| Lix | Waxtarka ugu weyn ee hawlgalka | |||

| 1 | Xawaaraha ugu badan | 1.2G | ||

| 2 | Waxtarka ugu weyn ee hawlgalka | 120m/min | ||

Afar, miiska cabbirka habka goynta

| Nooca walxaha | Dhumucda (mm) | Xawaaraha (m/min) | booska diiradda | Dhererka gooynta (mm) | Gaas | Nozzle Nooca | Hawada cadaadis (baar) | Awoodda leysarka (W) | goynta inta jeer (Hz) | wareegga waajibaadka% | saamayn goynta |

|

Q235B Birta kaarboon | 1 | 38 ~ 40 | 0 ~ -0.5 | 0.5 | N2 | hal lakab1.0 | 12 ~ 16 | 3000 | 5000 | 100 | dhalaalaya |

| 2 | |||||||||||

| 3 | 4 ~ 4.2 | 4.5 ~ 5.5 | 0.8 | O2 | lakabka labajibbaaran: 1.0 | 0.6 ~ 0.9 | 3000 | 5000 | 100 | ||

| 4 | 3.3 ~ 3.5 | 4.5 ~ 5.5 | 0.8 | O2 | lakabka labajibbaaran: 1.2 | 0.6 ~ 0.9 | 3000 | 5000 | 100 | ||

| 6 | 2.3 ~ 2.5 | 4.5 ~ 5.5 | 0.8 | O2 | lakabka labajibbaaran: 1.2 | 0.6 ~ 0.9 | 3000 | 5000 | 100 | ||

| 8 | 2.1 ~ 2.2 | 4.5 ~ 5.5 | 0.8 | O2 | lakabka labajibbaaran: 1.2 | 0.6 ~ 0.9 | 3000 | 5000 | 100 | ||

| 10 | 1.5 ~ 1.7 | 2 ~ 3 | 1.5 | O2 | lakabka labajibbaaran: 3.0 | 0.6 ~ 0.9 | 2200-2400 | 5000 | 100 | 磨砂面 | |

| 12 | 1.2 ~ 1.4 | 2 ~ 3 | 1.5 | O2 | lakabka labajibbaaran: 3.0 | 0.6 ~ 0.9 | 2200-2400 | 5000 | 100 | ||

| 14 | 1 ~ 1.1 | 2 ~ 3 | 1.5 | O2 | lakabka labajibbaaran: 4.0 | 0.6 ~ 0.9 | 2200-2400 | 5000 | 100 | ||

| 16 | 0.85 ~ 0.9 | 2 ~ 3 | 1.5 | O2 | lakabka labajibbaaran: 4.0 | 0.6 ~ 0.9 | 2200-2400 | 5000 | 100 | ||

| 18 | 0.7-0.75 | 2 ~ 3 | 1.5 | O2 | lakabka labajibbaaran: 4.0 | 0.6 ~ 0.9 | 2200-2400 | 5000 | 100 | ||

| 20 | 0.6 ~ 0.65 | 2 ~ 3.5 | 1.5 | O2 | lakabka labajibbaaran: 4.0 | 0.6 ~ 0.9 | 2200-2400 | 5000 | 100 | ||

| 22 | 0.5-0.55 | 2 ~ 3.5 | 1.5 | O2 | lakabka labajibbaaran: 4.0 | 0.6 ~ 0.9 | 2200-2400 | 5000 | 100 | ||

| 25 | 0.45 ~ 0.5 | 2 ~ 3.5 | 1.5 | O2 | lakabka labajibbaaran: 5.0 | 0.6 ~ 0.9 | 2200-2500 | 5000 | 100 | ||

| SUS304 不锈钢 | 1 | 35 ~ 37 | 0~-1 | 0.5 | N2 | Lakab keli ah: 1.0/1.2/1.5 | 12 ~ 16 | 3000 | 5000 | 100 | 无渣 |

| 2 | 13 ~ 15 | -1.5~-2 | 0.5 | N2 | Lakab keli ah: 1.5/2.0 | 12 ~ 16 | 3000 | 5000 | 100 | ||

| 3 | 7 ~ 8 | -2.5~-3 | 0.5 | N2 | Lakab keli ah: 2.0/2.5/3.0 | 16 ~ 20 | 3000 | 5000 | 100 | ||

| 4 | 4.5 ~ 5.5 | -3.5~-4 | 0.5 | N2 | Lakab keli ah: 3.0 | 16 ~ 20 | 3000 | 5000 | 100 | ||

| 6 | 1.7 ~ 1.9 | -5~-5.5 | 0.5 | N2 | Lakab keli ah: 3.5/4.0 | 16 ~ 20 | 3000 | 5000 | 100 | ||

| 8 | 0.8 ~ 1.0 | -6~-7 | 0.5 | N2 | Lakab keli ah: 4.0 | 16 ~ 20 | 3000 | 5000 | 100 | ||

| 10 | 0.6 ~ 0.7 | -7.5~-8.5 | 0.5 | N2 | Lakab keli ah: 4.0 | 16 ~ 20 | 3000 | 5000 | 100 | 少量挂渣 | |

| (6061) | 1 | 30 ~ 33 | -0.5~-1 | 0.5 | N2 | Lakab keli ah: 1.0/1.2/1.5 | 12 ~ 16 | 3000 | 5000 | 100 | |

| 2 | 10 ~ 12 | -1~-1.5 | 0.5 | N2 | Lakab keli ah: 1.5/2.0 | 12 ~ 16 | 3000 | 5000 | 100 | ||

| 3 | 5.5 ~ 5.9 | -2.5~-3 | 0.5 | N2 | Lakab keli ah: 2.0/2.5/3.0 | 16 ~ 20 | 3000 | 5000 | 100 | ||

| 4 | 2.8 ~ 3.2 | -3.5~-4 | 0.5 | N2 | Lakab keli ah: 3.0 | 16 ~ 20 | 3000 | 5000 | 100 | ||

| 6 | 0.7 ~ 0.8 | -5~-5.5 | 0.5 | N2 | Lakab keli ah: 3.5/4.0 | 16 ~ 20 | 3000 | 5000 | 100 | ||

| 8 | 0.5 ~ 0.6 | -6~-7 | 0.5 | N2 | Lakab keli ah: 4.0 | 16 ~ 20 | 3000 | 5000 | 100 | ||

| 黄铜 | 1 | ||||||||||

| 2 | |||||||||||

| 3 | 4.5 ~ 5 | -2~-2.5 | 0.5 | N2 | Lakab keli ah: 2.0/2.5/3.0 | 16 ~ 20 | 3000 | 5000 | 100 | ||

| 4 | 3 ~ 3.5 | -3~-3.5 | 0.5 | N2 | Lakab keli ah: 3.0 | 16 ~ 20 | 3000 | 5000 | 100 | ||

| 5 | |||||||||||

| 6 | 1 ~ 1.2 | -5~-5.5 | 0.5 | N2 | Lakab keli ah: 3.5/4.0 | 16 ~ 20 | 3000 | 5000 | 100 | ||

| 8 | |||||||||||

| 备注 | 1, In xogta goynta, dhexroor xudunta u ah fiber wax soo saarka ee laser 3000W waa 100 microns; | ||||||||||

| + | |||||||||||

| 3, Goynta gaasta kaaliyaha: oksijiinta dareeraha ah (nadiifinta 99.6%) nitrogen dareere ah (nadiifinta 99.995%); | |||||||||||

| 4, Sababtoo ah kala duwanaanshaha habka qalabka iyo habka goynta (qalabka mashiinka, qaboojinta biyaha, deegaanka, jarista gaaska gaaska iyo cadaadiska gaaska, iwm.) oo ay qaataan macaamiisha kala duwan, xogtani waa tixraac kaliya. | |||||||||||

5. Qalabka mashiinka iyo qalabka muhiimka ah

(1)

Sariirta sariirta waxay qabataa qaab dhismeedka rukhsadda leh ee Chaoxing Group, iyo guud ahaan daawaynta kaalmaynta walbahaarka gabowga waxaa lagu dhammeeyaa mashiin sax ah oo hal mar ah oo xarun mashiineed weyn ah si loo hubiyo qallafsanaanta sare, saxnaanta iyo xasilloonida;

(2) Mashiinnada Gear iyo biraha hagaha

Rack iyo pinion: Taiwan sax ah helical rack iyo pinion, P-class toosan hagaha sida walxaha gudbinta, sax sare iyo xawaaraha sare.

Xadiidka hagaha: Tilmaamaha toosan ee Taiwan ayaa la isticmaalaa, iyo hagayaal toosan oo sax ah oo culus oo leh nashqad qaabdhismeed la hagaajiyay ayaa la isku daray.Marka la barbardhigo hagayaasha toosan ee kale, culayska iyo adkaanta waa la wanaajiyey;waxay leedahay faa'iidooyinka xawaaraha sare, culeyska sarreeya, adagaanta sare iyo saxnaanta sare.

(2) Servo motor

Isticmaalka matoorada servo Japanese, waxay leedahay dardar-celin firfircoon oo wanaagsan, waxayna garwaaqsan tahay suurtogalnimada meelaynta sare.Degenaansho sare, saxnaan sare iyo dayactir la'aan.

(4) Wax yareeya

Qabsada wax-yaraha lagala soo degay.

faa'iido:

Saxnaanta sare: dib u celinta wax ka yar 3 daqiiqo, meeleyn sax ah.

Qalafsanaan sare, qulqulo sare: Isticmaalka rullaluistuyada isku dhafan waxay si weyn u wanaajisaa qallafsanaanta iyo qulqulka.

Dufanka Dufanka ah ma jiro: Isticmaal dufan badan, oo ay adag tahay in la kala saaro si aad si wax ku ool ah uga hortagto daadinta dufanka.

Dayactirka fudud: looma baahna in la beddelo dufan inta lagu jiro nolosha alaabta.

(5) Koronto dhaliyaha laysarka

Dooro cilmi-baarista wadajirka ah iyo horumarinta koronto-dhaliyaha laser fiber-ka, faa'iidooyinka koronto-dhaliyaha laysarka:

v Heerka beddelka sare ee electro-optical

v Tayada alwaaxda oo aad u fiican

v Nolol adeeg oo dheer

v Qiimaha hoose ee isticmaalka dhamaystiran

v Dayactirka bilaashka ah

6) Astaamaha madaxa laser fiber:

1. Qabso interface-ka QBH, kaas oo la qabsan kara dhammaan lasers-ka fiber-ka ee isku-xidhaha QBH.

2. Naqshad aan boodh celin lahayn oo ah muraayadda ilaalinta isku dhafka ah ee uu naqshadeeyay rukhsadda ikhtiraacida.

3. Si toos ah u hagaajinta diiradda, xawaaraha degdega ah, saxnaanta sare iyo hawlgalka habboon.

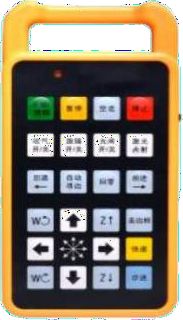

(7) Nidaamka xakamaynta:

Nidaamka xakamaynta CNC wuxuu ka kooban yahay qaybaha ugu muhiimsan sida nidaamka xakamaynta PC, darawalka iyo matoorkiisa servo.Nidaamka CNC leysarka gaarka ah ayaa la qaatay, kaas oo ka dhigan nidaamka CNC farsamaynta laser-ka ugu xirfadda badan.CNC-ga is haysta iyo modular-ku waxa uu buuxiyaa baahiyaha isticmaalayaasha isticmaalaya hababka CNC ee waxqabadka sare leh oo leh qiimeheeda/waxqabadka wanaagsan.

Waxqabadka ugu sarreeya:

Ø Farsamada heerka koowaad iyo hufnaanta

Tiknoolajiyada cusub ee CNC iyo qaab dhismeedka CNC ee furan oo leh Intel dual-core CPUs ayaa siiya isticmaaleyaasha dabacsanaan badan marka ay dooranayaan qaybaha CNC iyo hal-tallaabo oo ka horreeya waxqabadka CNC.

Ø Qaab-dhismeedka qaab-dhismeedka

l Mashiinka xawaaraha sare leh

l Aaladaha mishiinada xawaaraha sare waxay u baahan yihiin wakhti wareeg ah oo aad u gaaban (PA waxay gaartaa 7200 blocks/sec) iyo algorithms-yada gaarka ah iyo hawlaha isgaarsiinta."Hawsha wax-akhriska ka hor ee la qabsiga" waxay horay u socodsiin doontaa 1000 blocks ee barnaamijka waqtiga dhabta ah, waxayna xisaabin doontaa heerka ugu sarreeya ee quudinta gudaha xuduudaha barnaamijka iyo xaddidaadda si loo buuxiyo shuruudaha mashiinnada adag.

Ø Saxnaanta

Shuruudaha wax soo saarka sare, saxnaanta sare iyo tayada wanaagsan ee dusha sare ayaa si joogto ah u kordhaya.

Ø Bani-aadamka-mashiinnada

Hawlaha ogaanshaha dhammaystiran si dhakhso ah loo helo cilladaha;noocyo kala duwan oo gaasaska caawiyayaasha ah ayaa si fudud loogu beddeli karaa iyada oo loo marayo nidaamka xakamaynta tirada.

Waxay leedahay laybareeriga cabbirka habka goynta khabiirka laser-ka iyo interface-ka khabiirka khibradda-saaxiibtinimo ee maktabadda, kaas oo wax ka beddeli kara cabbirrada habka goynta laysarka waqtiga dhabta ah ee interface-ka.

Isku xirka isgaarsiinta Ethernet wuxuu si toos ah ula xiriiri karaa kumbuyuutarka wuxuuna wareejin karaa faylasha barnaamijka.Iyada oo leh muujinta heerka iyo muujinta shaqada booska hadda.

Meesha ay ku kaydsan tahay Hard Disk-gu waa 250G, barnaamijka farsamaynta waxa si toos ah looga soo wici karaa Hard Disk-ga, sidaa awgeed laguma xaddidna xusuusta nidaamka.Shaqada ogaanshaha fog, nidaamka servo digital.Muujinta LCD midabka.

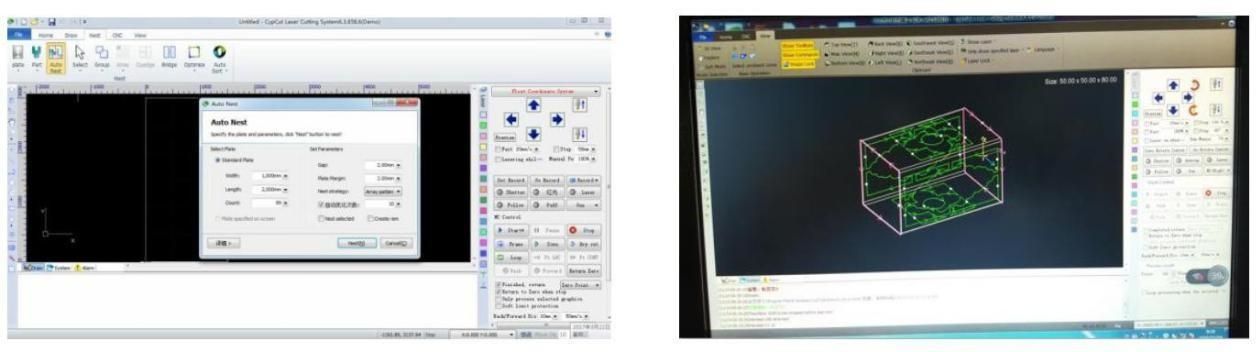

(8) Naqshadeynta barnaamijka iyo sooftiweerka buul

Cypcut iyo Cuytube waa nidaam goynta birta ah oo awood leh iyo software-qorista caqli-gal ah, oo ay ku jiraan habka goynta laysarka, hawlaha buulka caadiga ah iyo xakamaynta farsamaynta laysarka.Hawlaha ugu muhiimsan waxaa ka mid ah habaynta garaafyada, dejinta halbeegyada, habaynta habka goynta caadada ah, qaabaynta, qorshaynta dariiqa, jilitaanka, iyo xakamaynta habka goynta.

9) Habka qaboojinta

Qabo nidaamka qaboojiyaha Wuhan Hanli si aad u qaboojiso koronto dhaliyaha laysarka, si hufan u qaboojiso qaybaha indhaha iyo madaxa goynta.Cutubka qaboojinta ayaa leh wareegga biyaha qaboojinta oo xiran.

(10) Qaboojiyaha warshadaha

Heerkulka hawada sare ee warshadaha ee u go'ay ayaa loo isticmaalaa si wax ku ool ah loo hubiyo hawo nadiif ah iyo heerkulka deegaanka ee golaha wasiirada, xakamaynta tooska ah ee caqliga leh, nidaaminta caqliga leh iyadoo loo eegayo heerkulka jawiga ee golaha wasiirada, ilaalinta filter labajibaaran, oo si buuxda ula qabsan kara jawi adag sida deegaan liidata. siigada badan, iyo heerkulka sare.Si weyn u wanaaji nolosha adeegga qaybaha korantada ee saxda ah.

6. Adeegyada Farsamada

(1) Shaqada qalabka iyo shuruudaha deegaanka

| Maya | Faahfaahin |

| 1 | Korontada: 100KVA |

| 2 | Shuruudaha sahayda korantada: (koronto nidaamsan ayaa lagula talinayaa) Korontada la qiimeeyay: 380V/50Hz xasilloonida korantada ee saddexda waji ah +10 Xeerarka Korontada soo-saarka: <2 |

| 3 | Aaladda sahayda hawada cufan (taangi hawo kaydinta ayaa lagula talinayaa) Mugga: 0.6 m3 Cadaadis la qiimeeyay: 20 bar |

1. Golaha awood qaybinta goobta: 380V, 50Hz, saddex-waji afar-silig, awoodda aan ka yarayn 100 KVA, oo leh ilaalinta gaaban gaaban, iwm.

2. Qalabka waa in lagu rakibaa dhul gaar ah, caabbinta dhulkana waa in aanay ka badnayn 4Ω.

3. Bixi qalabka lagama maarmaanka u ah qaadista iyo shaqaalaha.

4. Bixi walxaha sida taarikada birta ah ee looga baahan yahay goobta goobta ee qalabka.

5. Sii kaarka ku meel gaadhka ah ee shaqaalaha ciribtirka.

6. Xaaladaha kaaliyaha ah ee looga baahan yahay hawlgalka caadiga ah ee qalabka goynta laysarka: a.Goynta gaaska caawiya (N2, O2);

b.Nidaamka sahayda hawada cufan ee aan biyaha lahayn iyo saliid la'aanta.

7. Meelaynta qalabka iyo shuruudaha aasaasiga ah: Aasaaska waa la taaban karo.

(3) Rakibaadda iyo tababarka

1. Rakibaadda:

30 maalmood gudahood ka dib marka la saxiixo heshiiska ganacsiga, sii isticmaalaha qorshaha dabaqa rakibaadda (oo ay ku jiraan shuruudaha rakibidda shaqooyinka madaniga ah, biyaha, korontada, gaaska, tuubooyinka, isdhexgalka, iwm.).

Qalabka ayaa lagu rakibay warshadda isticmaalaha, waxaana looga baahan yahay qofka isticmaalaya inuu bixiyo meel ku filan, koronto iyo hawo-siin uu ku rakibo qalabka.Rakibaadda waxaa fulinaya alaab-qeybiyaha injineerada aadka u tababaran.Alaab-qeybiyaha ayaa mas'uul ka ah rakibidda qalabka (oo ay ku jiraan rakibidda tuubooyinka qiiqa) iyo cilladaha.Isticmaaluhu wuxuu mas'uul ka yahay shaqada madaniga ah ee rakibidda qalabka, iyo tuubooyinka biyaha, tuubooyinka gaaska, iyo xadhkaha korontada ayaa ku xiran qalabka mashiinka uu u qoondeeyey injineerka alaab-qeybiyaha, iyo Xisbiga B ayaa mas'uul ka ah dhuumaha ku xiran qalabka mashiinka. laakiin adeegsaduhu waa inuu siiyaa injineeriyaha alaab-qeybiyaha wadashaqeynta lagama maarmaanka ah iyo caawinta rakibidda iyo ciribtirka qalabka.

2. Tababarka:

Tababarka shaqaalaha waxaa lagu dhammeeyaa warshadda iibsadaha, inta badan si ay u bartaan dayactirka qalabka, hawlgalka, ilaalinta laysarka, farsamaynta tignoolajiyada, graphic editing, cilad guud, iwm. Ardayda waxaa looga baahan yahay in ay fahmaan hawlgalka kombiyuutarka iyo in ay leeyihiin aqoon aasaasi ah oo ku saabsan sawirka AutoCAD.

(4) Ka dib iibka

1. Ka dib aqbalaadda, muddada dammaanadda tayada ee mashiinka oo dhan waa laba sano.Haddii qaybaha nidaamka ay leeyihiin dhibaatooyin tayo leh inta lagu jiro muddada dammaanadda, injineerada adeegga ee sida wanaagsan u tababaran ee shirkadeena ayaa ku siin doona adeeg telefoon ama goobta wakhti kasta.Jawaabta taleefanka 2 saacadood gudahood

, adeega goobta waa 24 saacadood gudahood.

2.During muddada dammaanadda ee qalabka, shirkadeena ayaa mas'uul ka ah beddelka lacag la'aan ah ee qaybaha iyo adeegyada wixii dhaawac ah ama dhaawac ay keento tayada qalabka laftiisa, marka laga reebo isticmaalka caadiga ah (sida lenses indhaha, nozzles) iyo kuwa in waxay mas'uul ka yihiin adeegsadaha hawlgalkiisa sharci darrada ah.

3.Ka baxsan muddada dammaanadda qalabka, injineerada adeegga si fiican u tababaran ee shirkadeena ayaa bixin doona adeegga taleefanka ama goobta wakhti kasta.Jawaabta telefoonku waa 2 saacadood gudahooda iyo adeegga goobta 48 saacadood gudahood.Haddii beddelka agabka spare-ka ay ku lug leedahay, shirkadeena waxay ku soo dalacaysaa qiimaha qaybaha qiimaha suuqa, adiguna waxaad masuul ka noqon doontaa kharashaadka safarka injineerada dayactirka shirkadeena.