Mashiinka calaamadaynta laser UV

Mashiinka calaamadaynta laser UV waa taxane ah mashiinada calaamadaynta laysarka, markaa mabda'a ayaa la mid ah mashiinka calaamadaynta laysarka, kaas oo ah in la isticmaalo laydhka laysarka si loo sameeyo calaamado joogto ah oogooyin kala duwan.Saamaynta calaamadaynta ayaa ah in si toos ah loo jebiyo silsiladda molecular ee maaddada iyada oo loo marayo laser-mawjadda gaaban (oo ka duwan uumiga walxaha dusha sare ee ay soo saarto laser-dheer si ay u muujiso walxaha qoto dheer), si ay u muujiyaan qaababka iyo jilayaasha loo baahan yahay .

Laser UV waxaa loo isticmaali karaa calaamadaynta aadka u fiican iyo calaamadaynta walxaha khaaska ah sababtoo ah goobtiisa yar ee diiradda iyo meelaynta yar ee kuleylku saameeyay.Waa badeecada la doorbido macaamiisha leh shuruudaha sare ee calaamadaynta saamaynta.Marka lagu daro naxaasta, laysarka UV wuxuu ku habboon yahay in lagu farsameeyo agabyo kala duwan.Ma aha oo kaliya tayada alwaaxdu waa wanaagsan tahay, meesha diiradda la saarayaa waa yar tahay, calaamadaynta aadka u fiican waa la xaqiijin karaa;Baaxadda codsigu waa ka ballaaran yahay;Meesha kulaylku saameeyey aad bay u yar tahay mana soo saari doonto saamaynta kulaylka iyo gubashada walxaha;Xawaaraha calaamadaynta degdega ah iyo waxtarka sare;Mashiinka oo dhan wuxuu leeyahay faa'iidooyinka waxqabadka xasilloon, cabbir yar iyo isticmaalka tamarta hooseeya.

1. Iyada oo tayada sare leh iyo meel iftiin aad u yar, calaamad aad u fiican ayaa lagu gaari karaa;

2. Tayada calaamadaynta waa mid aad u sareysa: 355nm dhererka dhererka wax soo saarka wuxuu yareeyaa saameynta kulaylka ee shaqada;

3. Nooca galvanometer-ka madaxa calaamadaynta saxda ah wuxuu leeyahay saameyn wanaagsan oo si isdaba joog ah ayaa loo farsameyn karaa;

4. Barta iftiinka saxda ah ee saxda ah ee saxda ah waxay hubisaa natiijada calaamadaynta saxda ah;

5. Habka calaamadayntu waa mid aan lala xidhiidhin, saamayntuna waa mid joogto ah;

6. Meesha kulaylku saameeyaa waa mid aad u yar, ma jiri doonto wax saameyn ah oo kuleyl ah, maaddaduna ma noqon doonto mid qallafsan ama guban;

7. Xawaaraha calaamadaynta degdega ah iyo waxtarka sare;

8. Mashiinka oo dhan wuxuu leeyahay waxqabad xasilloon, cabbir yar iyo isticmaalka tamarta hoose.

9.Waxay ku habboon tahay qalabka wax lagu farsameeyo ee leh falcelinta shucaaca kulaylka ee weyn.

10. Waxay la shaqayn kartaa khadka wax-soo-saarka si ay si toos ah u rarto una dejiso agabka oo ay si toos ah u soo dejiso una dhoofiso agab;

11. Ku habboon in lagu calaamadiyo inta badan biraha iyo alaabta aan biraha ahayn;

12. Nidaam qalliin oo dabacsan oo ku habboon: habka hawlgalka user-saaxiibtinimo iyo xasilloonida hawlgalka qalabka;

13. Habayn toos ah iyo wax ka beddelka calaamadaha qoraalka, sawirada garaafyada, koodhadhka bar-code, nambarada laba-geesoodka ah, lambarada taxanaha ah, iwm;

Taageer PLT, PCX, DXF, BMP, JPG iyo qaabab faylal kale, oo si toos ah u isticmaal farta TTF;

| Magaca alaabta | Mashiinka calaamadaynta laser Uv |

| Awoodda leysarka | 3w / 5w / 10w |

| Nolosha isticmaalka leysarka | 10000 saacadood (nolosha dhabta ahi waxay kuxirantahay shuruudaha iyo deegaanka isticmaalka) |

| Dhererka hirarka leysarka | 355nm |

| Celceliska awoodda wax soo saarka | 0-3W si joogto ah loo hagaajin karo, ikhtiyaari ah: 0-5W/0-10W si joogto ah loo hagaajin karo |

| Kala duwanaanshaha soo noqnoqda qaabaynta | 10kHz-200kHz |

| Tayada beam | M2 <1.1 |

| Xawaaraha toosan ee galvanometer | 12000mm/s |

| Calaamadee dabeecadda | Xawaaraha 300 xaraf// Farta Roomaanka, dhererka ereyga 1mm |

| Saxnaanta calaamadaynta soo noqnoqda | ± 0.003mm |

| Balaadhka khadka calaamadaynta | 0012mm |

| Dhererka jilaha | 0.15mm |

| Calaamadaynta qoto dheer | 0.2mm (waxay kuxirantahay nooca gaarka ah iyo walxaha) |

| Aagga calaamadaynta | 110 * 110mm |

| Dhererka xoogga shaqada | 163 ± 2mm |

| Habka qaboojinta | biyo qaboojin |

| Awood la qiimeeyay | ≤ 1kW |

| danab leysarka | ≤ 1kW |

| danab leysarka | 220V/hal-waji/50Hz/10A |

| Shuruudaha deegaanka | - 5 ~ 45 ° C;Qoyaanka <90% |

Guud ahaan, mashiinka calaamadaynta laysarka ee caadiga ah (mashiinka calaamadaynta laser fiber optic, mashiinka calaamadaynta laser co2) inta badan waxay isticmaashaa saamaynta kulaylka ee laser si ay u gubaan dusha walxaha si ay u sameeyaan isbeddel midab ama uumi lakabka alaabta si ay u daadiyaan walxaha hoose si ay u sameeyaan. calaamad.Si kastaba ha ahaatee, calaamaddan lagu sameeyay saamaynta kulaylka waxay leedahay cillado weyn oo ku jira warshadaha baakadaha jilicsan ee jilicsan.Kaarboon-dioxide garaacista filimka jilicsan ayaa si fudud u keeni doonta filimka jilicsan inuu burburiyo oo daadanayo, sidaas darteed saameynaya nolosha shelf ee cuntada.Ma jirto wax jawaab ah marka leysarka fiber indhaha ah uu ku dhufto filimo badan oo balaastik ah, iyo qoto dheeraanta xudunta fiilada indhaha (hal millimitir oo keliya) waa sahlan tahay in la akhriyo marka bacdu ruxdo ama gariirto.Muuqaalka iftiinka buluuga ah wuxuu si fiican u xalliyaa dhibaatooyinka kor ku xusan.Mashiinka calaamadaynta laser ultraviolet wuxuu isticmaalaa 355 nm mawjadda dhererka gaaban ee ultraviolet laser, taas oo aad ugu fiican nuugista filimka jilicsan.Mabda'a mashiinka calaamadaynta laysarka ultraviolet waa in 355 nm iftiinka ultraviolet uu iftiimiyo daboolka dusha sare ee filimka jilicsan, taasoo keenaysa isbeddel kiimiko ah lakabka, sidaas darteed soo saarida isbeddelka midabka.Sababtoo ah iftiinka ultraviolet kaliya wuxuu ka falceliyaa daboolka, ma jebin doono baakadaha filimka jilicsan.

Codsiga:

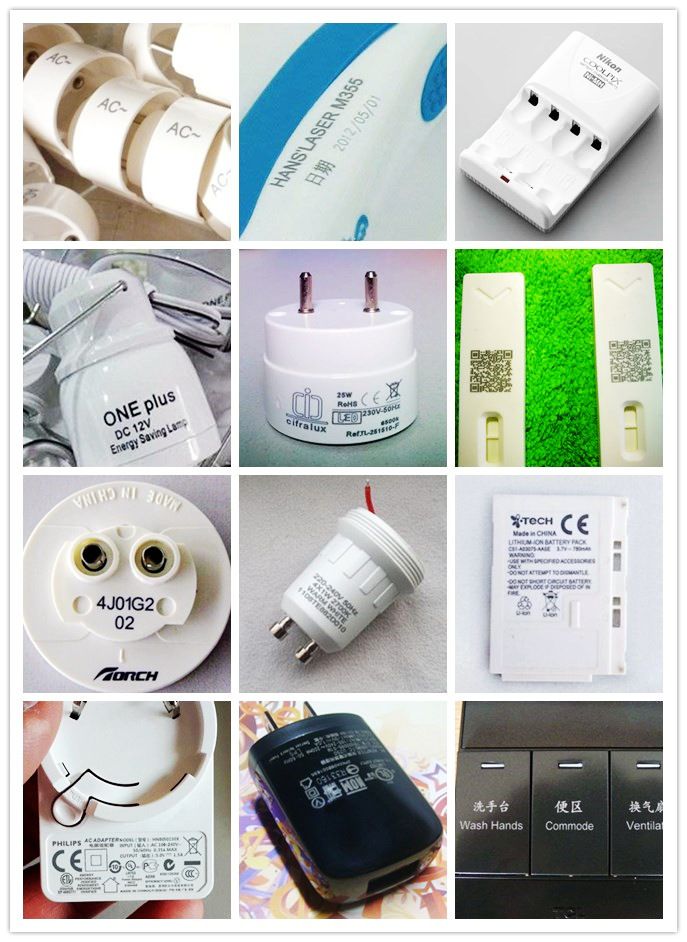

Mashiinka calaamadaynta laser UV ayaa si weyn loo isticmaalaa.Loo isticmaalo calaamadaynta aadka u fiican iyo xardho, gaar ahaan cuntada iyo bacaha daawada

Warshadaha codsiga sida calaamadaynta alaabta baakadaha, qodista godadka, qaybinta xawaaraha sare ee alaabta quraarada iyo goynta garaafka adag ee maraqa silikoon.

Calaamadaynta sabuuradda PCB iyo qorista;Microhole iyo farsamaynta daloolka indha la'aanta ee wafer silikoon;LCD muraayadda laba-geesoodka ah calaamadaynta koodka, feerka dusha muraayadaha, calaamadaynta dusha birta, furayaasha caagga ah, qaybaha elektaroonigga ah, hadiyadaha, qalabka isgaarsiinta, qalabka dhismaha, iwm. Inta badan loo isticmaalo warshadaha caadiga ah waa in la jebiyo muraayadda.